Key Takeaways:

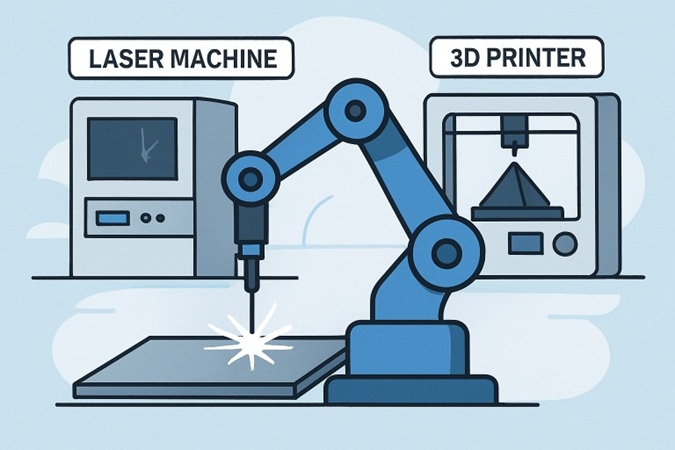

- Laser cutting and 3D metal printing are setting new industry standards for precision and design flexibility.

- Automation, robotics, and AI are streamlining operations, enhancing quality assurance, and lowering manual intervention.

- Sustainable methods, such as recycling and energy-efficient processing, are increasingly prioritized.

Custom metal fabrication is entering a new era, marked by rapid technological advancements and shifting industry priorities. As fabricators look to gain a competitive edge and satisfy increasingly demanding project requirements, they are turning to cutting-edge tools and more intelligent workflows. Providers like Elite Weld & Fab are at the forefront, incorporating both traditional craftsmanship and innovative new techniques to set new benchmarks for quality, efficiency, and sustainability. These developments not only enable greater creativity in design and engineering but also respond to calls for eco-conscious manufacturing and shorter project timelines.

Modern custom metal fabrication shops now benefit from high-precision equipment, automation, and advanced computer-guided systems that minimize errors and lower costs. This technology-driven transformation enables intricate product designs and repeatable processes, while also supporting sustainable initiatives focused on material reuse and waste reduction. The combination of technological innovation and experienced fabricators is fueling a new wave of possibilities in both industrial and creative applications.

With complex demands driving the industry, specialists are pushing boundaries in metal shaping, joining, and finishing, resulting in stronger, lighter, and more resilient products. As these innovations unfold, the benefits reach far beyond the workshop, positively impacting construction, transportation, healthcare, and consumer products alike.

Adopting these forward-thinking practices not only yields better outcomes for clients but also supports broader trends in digital transformation and sustainability, as reported by industry leaders such as McKinsey.

Table of Contents

Laser Cutting & Advanced CNC Machining

Laser cutting has become indispensable in custom metal fabrication thanks to its high accuracy, speed, and ability to produce complex shapes. The latest generation of fiber lasers can achieve ultra-fine tolerances with minimal heat distortion, allowing fabricators to work confidently with a wide range of metals, including steel, aluminum, and specialty alloys. This level of precision reduces material waste, lowers finishing needs, and supports faster project turnarounds. When paired with multi-axis CNC (Computer Numerical Control) machining, shops can achieve even higher complexity in parts manufacturing. Multi-axis CNC machines streamline the transition from digital designs to physical components, supporting complex contours and intricate features that traditional machines cannot address. The combination of these technologies is enabling previously unthinkable design innovation, supporting industries from aerospace to architectural metalwork.

3D Metal Printing & Additive Manufacturing

3D Metal Printing & Additive Manufacturing

The integration of 3D metal printing, or metal additive manufacturing, has unlocked radical new possibilities for custom fabrication. Unlike subtractive methods, which cut away from a solid block, 3D printing builds parts layer by layer directly from digital files, enabling fabrication of intricate, lightweight structures with internal geometries that remain impossible with conventional techniques. Designers and engineers are embracing the ability to prototype quickly and iterate designs in real-time, reducing time-to-market for new products. Recent advances in printable alloys and hybrid composites have led to parts with superior mechanical and thermal performance, supporting deployment in harsh environments such as aerospace propulsion systems and biomedical implants. The efficiency and versatility of additive manufacturing continue to drive its expansion across both prototyping and low-to-medium batch production, making it an essential capability for modern fabrication shops. More details on the growing impact of 3D metal printing can be found at Forbes.

Automation & Robotics Integration

The adoption of automation technologies and robotics in custom metal fabrication is elevating both productivity and safety. Robots now handle tasks such as welding, deburring, and material transfer with consistent high speed and accuracy. These systems minimize human exposure to dangerous environments and repetitive motions, lowering both risks and labor costs. The latest innovation involves collaborative robots or ‘cobots’, which can interact safely with human operators and adapt to evolving production schedules without extensive reprogramming. As demand fluctuates, cobots enable rapid shifts between project types and scale up output without sacrificing quality. Automation in scheduling and inventory management also accelerates lead times and keeps projects running smoothly from commencement to delivery.

Artificial Intelligence In Quality Control

Artificial Intelligence is making quality assurance in metal fabrication more predictive and precise. AI-driven vision systems, powered by machine learning algorithms, review millions of data points from visual inspections to catch minor inconsistencies and emerging flaws. These proactive tools catch issues that manual checks might miss, ensuring consistently high-quality outputs and slashing expensive rework rates. Machine learning models can also analyze production data over time to suggest process improvements, further enhancing product reliability. The adoption of AI not only lifts the standard for what can be achieved in quality control but also positions fabricators to meet rising client expectations for flawless results.

Sustainable Practices In Metal Fabrication

Sustainability has become a priority across manufacturing, including custom metal fabrication. Advanced techniques like laser and waterjet cutting use less energy and produce less scrap than older processes. Responsible recycling practices and closed-loop systems minimize raw material consumption and keep valuable metals in use longer. Shops are also investing in energy-efficient machinery and seeking suppliers with strong environmental records. Eco-friendly designs, often created with lighter, stronger alloys, support resource conservation over the entire product lifecycle. Clients are increasingly demanding documentation of these sustainability practices, making them both a market differentiator and an ethical imperative.

Augmented Reality For Design & Visualization

Augmented Reality is bridging the gap between design intent and finished metalwork. Fabricators and clients use AR technology to superimpose digital prototypes onto real-world settings, allowing them to fully visualize how a custom part or assembly will look once installed. This accelerates the feedback loop, makes it easier to spot design conflicts, and reduces the risk of costly redesigns late in the process. AR also offers clients hands-on involvement throughout design and fabrication, ensuring satisfaction with the final result. As AR becomes more user-friendly, it is quickly moving from a novelty to a standard expectation in forward-looking fabrication operations.

Conclusion

Technological innovation and sustainable engineering are transforming custom metal fabrication for 2026 and beyond. With laser cutting, 3D printing, automation, AI, and AR enabling greater creativity and efficiency, shops are empowered to meet high standards for complexity, speed, and environmental responsibility. Companies that embrace these trends are best equipped to deliver value, quality, and a competitive edge in a rapidly changing industry landscape.