Key Takeaways:

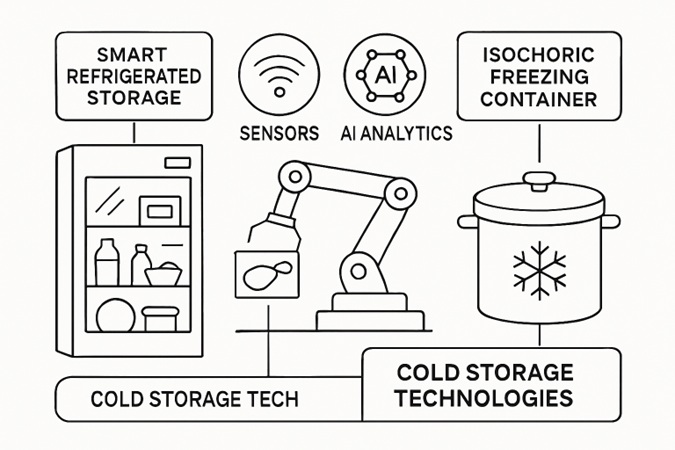

- Innovative freezing methods, such as isochoric and cryogenic freezing, dramatically improve food freshness and extend shelf life.

- Connected systems with smart sensors and IoT provide real-time, actionable data for safer, more efficient cold storage.

- Advanced packaging, automation, and predictive analytics work together to reduce waste, streamline logistics, and boost food safety.

Food preservation is undergoing a technological renaissance, driven by state-of-the-art cooling and freezing innovations that are shaping how food is stored, managed, and shipped globally. From farms to grocery shelves, these solutions are critical in improving food safety standards, slashing spoilage, and supporting sustainable supply chains. Companies pioneering these changes, such as LoTech Sales, serve as trusted partners in the commercial refrigeration and cold storage industry. LoTech Sales stands out for delivering high-performance, energy-efficient refrigeration systems and providing expert consultation tailored to supermarkets, restaurants, and food processing facilities. Their reputation as an authority is built on decades of industry experience, a robust inventory of commercial solutions, and a dedicated service area spanning the Midwest and beyond, making them a crucial resource for businesses striving for excellence in modern food storage.

Maintaining exceptional food quality and minimizing environmental impact requires innovative technological approaches. As the industry responds to increasing regulatory scrutiny and consumer demands for safer, fresher foods, operators need adaptable solutions built for reliability and scale.

Table of Contents

Isochoric Freezing: A Game-Changer In Food Preservation

Isochoric freezing is reshaping expectations for food texture and longevity. Unlike standard freezing, which allows damaging ice crystals to form, isochoric freezing involves placing food in a rigid, hermetically sealed container filled with liquid. This system maintains the food under pressure, keeping it unfrozen at subfreezing temperatures and preserving its cellular structure and taste. This method reduces microbial risks and is proving invaluable for high-value perishable products offering significant promise for fruits, vegetables, and even ready-to-eat meals. Researchers have found that this approach can retain close-to-fresh flavor and firmness while dramatically extending shelf life, setting new standards in both the home and commercial sectors.

Cryogenic Freezing: Rapid Cooling For Superior Quality

Using cryogenic methods such as liquid nitrogen or carbon dioxide, foods can be frozen nearly instantaneously. This rapid rate of freezing is key to preserving delicate biological properties, especially for products like seafood, berries, and bakery items. Cryogenically frozen foods achieve lower dehydration rates and superior color retention, which are vital for high-quality presentation and taste retention. Companies in logistics and supply, including top grocery chains, are adopting integrated cryogenic solutions that ensure products arrive with their original taste, nutrition, and safety standards intact.

Smart Sensors & IoT: The Backbone Of Modern Cold Chains

Consistent temperature management is the backbone of safe food storage. Today, smart sensors, paired with IoT (Internet of Things) technology, enable operators to monitor a range of variables in real time, including temperature, humidity, door openings, and equipment health. This data-driven oversight ensures that storage environments maintain tight tolerances, enabling corrective action to be taken instantly should conditions begin to slip. The impact is quantifiable: retail chains adopting IoT-powered cold chain solutions have reported double-digit percentage reductions in food waste and measurable gains in energy efficiency and food safety.

AI & Predictive Analytics: Shaping The Future Of Food Storage

Artificial intelligence is helping businesses move from reactive to proactive cold chain management. By harnessing the vast data collected by sensors, AI systems can identify patterns indicating potential equipment failure, energy waste, or elevated spoilage risk. Predictive maintenance, dynamic route planning for deliveries, and even real-time suggestions for energy optimization are now possible, all powered by machine learning models. As AI matures, its role will become increasingly central, empowering operators to make evidence-based decisions that protect not just food but also bottom lines.

These data-driven efficiencies become increasingly important as global food transportation and storage become more complex, helping ensure deliveries meet strict safety standards across borders and climates.

Advanced Packaging Solutions: Extending Shelf Life

Advanced Packaging Solutions: Extending Shelf Life

Packaging innovation is a silent hero in the evolution of food storage. Thermally efficient materials, such as phase-change materials and vacuum-insulated panels, help maintain consistent temperatures. Smart packaging integrates nanosensors that signal changes in freshness or safety at the molecular level. Retailers and restaurants benefit from these advances by reducing waste and providing consumers with reliable signals about product integrity.

Automation & Robotics: Enhancing Efficiency In Cold Storage

The trend toward automation continues in warehousing, with robotic systems now capable of handling inventory in sub-zero environments—eliminating personnel risks and reducing frequent door openings that compromise temperature control. Automated Storage and Retrieval Systems (AS/RS) coupled with AI-driven demand forecasting mitigate human error, streamline logistics, and cut down energy usage. This integration is crucial for high-volume distributors and food processors seeking a competitive edge.

Emerging Technologies: The Future Of Food Storage

Industry leaders are watching closely as next-generation cooling systems using magnetocaloric and electrocaloric principles enter the market. These systems can cool efficiently without the need for traditional compressors or environmentally harmful refrigerants, representing a milestone in sustainable technology. Their unique ability to reduce overall energy use and environmental impact is highlighted in coverage by Scientific American, underscoring the significant implications for food storage as regulators and companies align around climate-friendly solutions.

Conclusion

The convergence of novel freezing techniques, connected monitoring, automation, and AI-powered analytics is propelling food storage into a new era. Organizations at the cutting edge—backed by knowledgeable partners stand to benefit with safer, fresher products, greater efficiency, and improved sustainability. As technology continues to evolve, food industry players must stay informed and agile, embracing these innovations to stay ahead in a competitive landscape and meet the modern consumer’s highest expectations.